From liquid to solid, our complete magnesium alloy production chain provides you with the best all-in-one customized services.

RAW MATERIAL

MANUFACTURING

R&D

MANAGE

【 Magnesium Raw Materials 】

Proprietary raw material resources, controlling material quality from the source

Pinda focuses on the production of magnesium metal-related materials.

Including the process from magnesium ore extraction to the manufacturing of magnesium alloys.

The quality of Pinda's materials meets standards ranging from aluminum can applications to aerospace satellites.

All can meet customers' various and complex needs for magnesium alloy materials.

We can provide various types of magnesium ingots, magnesium bars, magnesium plates, and different alloy grades to meet your needs.

(AZ91D, AM60B, AZ31B, AM50-60, etc.)。

【 Magnesium Alloy Die Casting 】

From bicycle components to in-car entertainment systems, our diverse machinery meets your customization needs.

One of Pinda's areas of expertise is magnesium alloy die casting, with a wide range of machinery (Die-Casting, Thixo molding) ranging from 125 tons to 3000 tons. We focus on manufacturing products such as automotive panels, laptop casings, and smartphone housings. With cutting-edge technology and years of experience, we ensure the production of high-quality and highly precise magnesium alloy products.

【 Light metal forging 】

High-speed 3D forging technology, revolutionizing traditional processing methods, is perfectly applied to lightweight, heat dissipation, and complex-shaped components.

Pinda, with over 20 years of experience, has independently developed a unique forging process—Uni Forge—that focuses on the precise forming of lightweight metals such as magnesium, copper, and titanium alloys. This technology is applicable in manufacturing 3C products, such as high-efficiency heat sinks, ensuring that products meet high-specification standards. Uni Forge not only offers versatility to address various metal forging needs but also achieves complex structures and high-precision manufacturing.

【 Magnesium Recycle 】

Refining and processing of magnesium scrap to achieve global magnesium recycling.

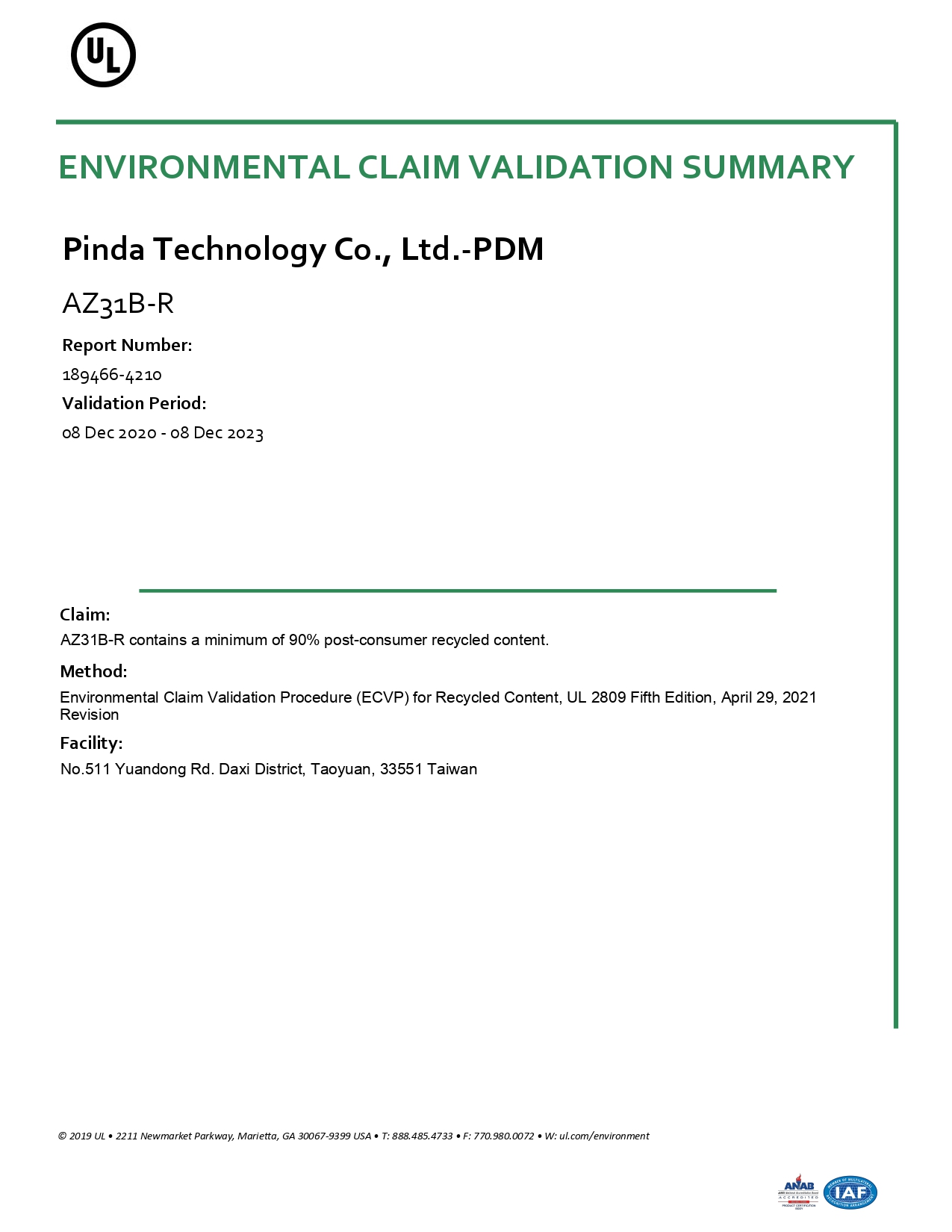

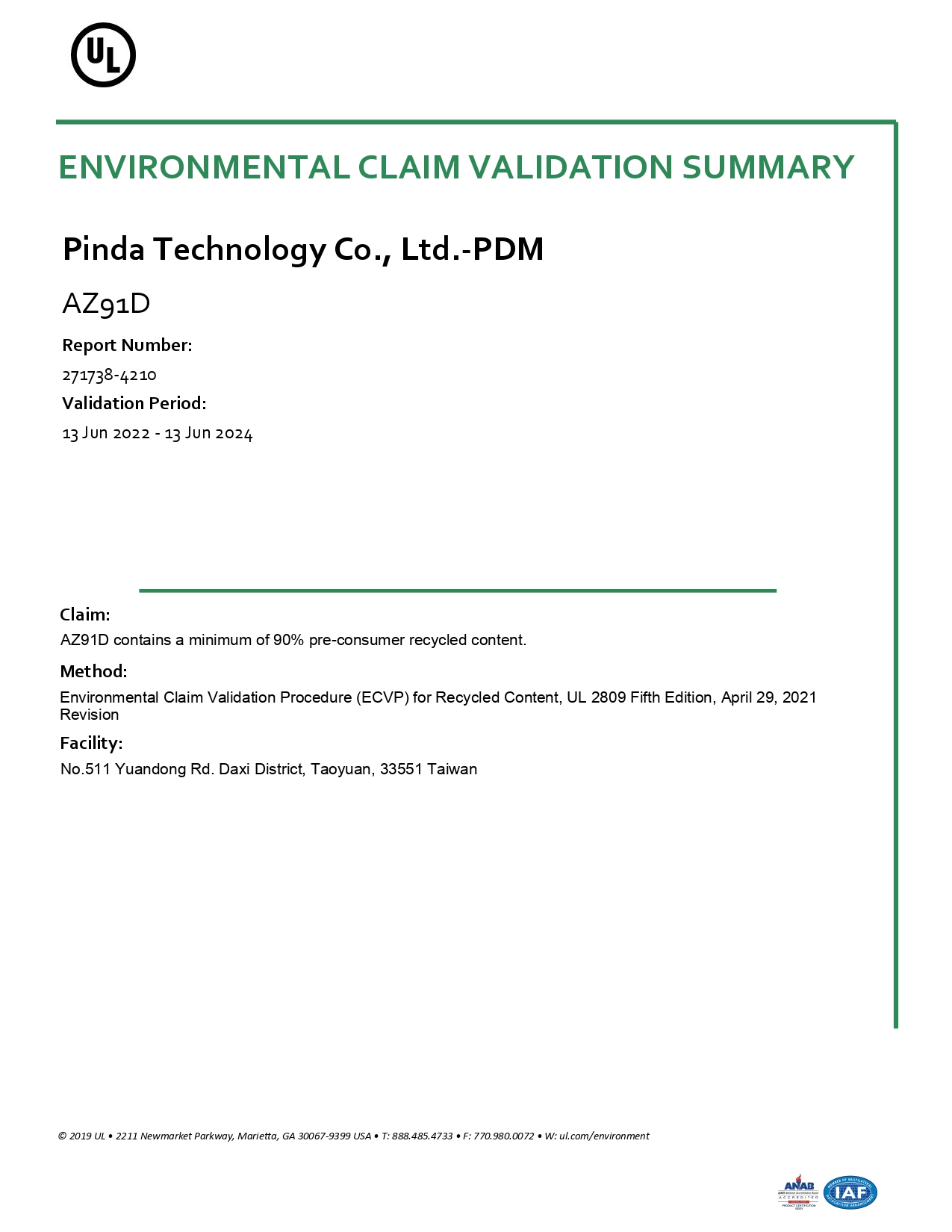

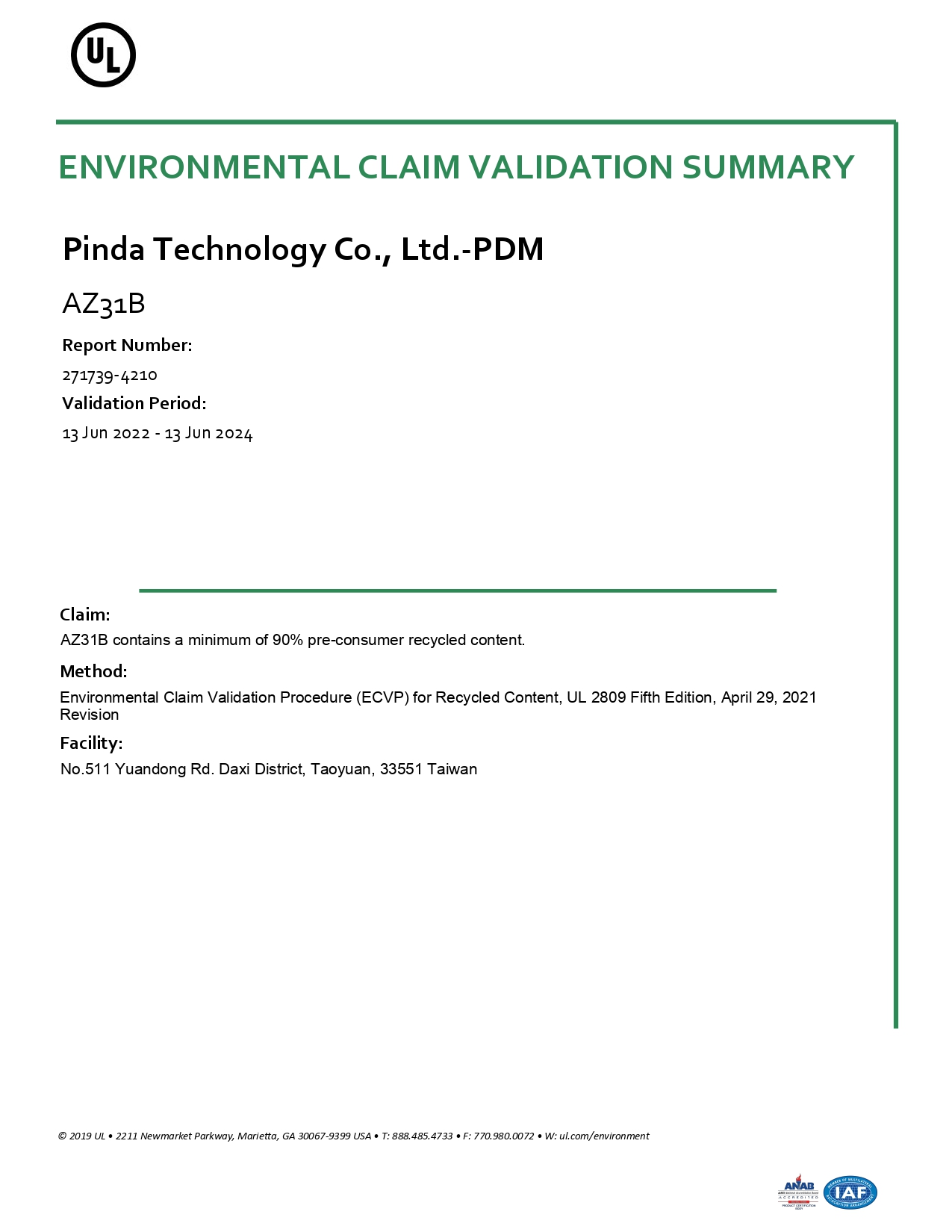

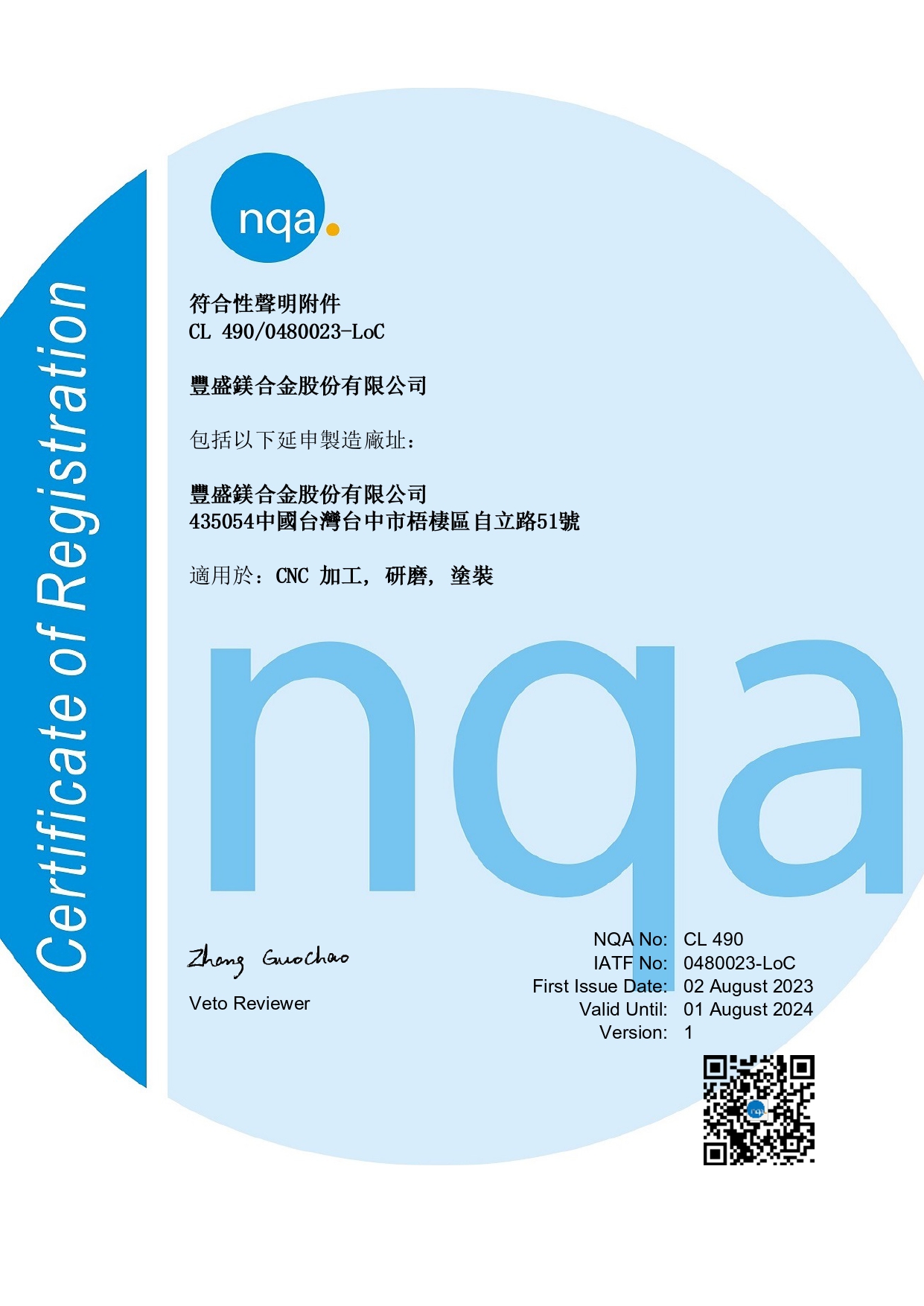

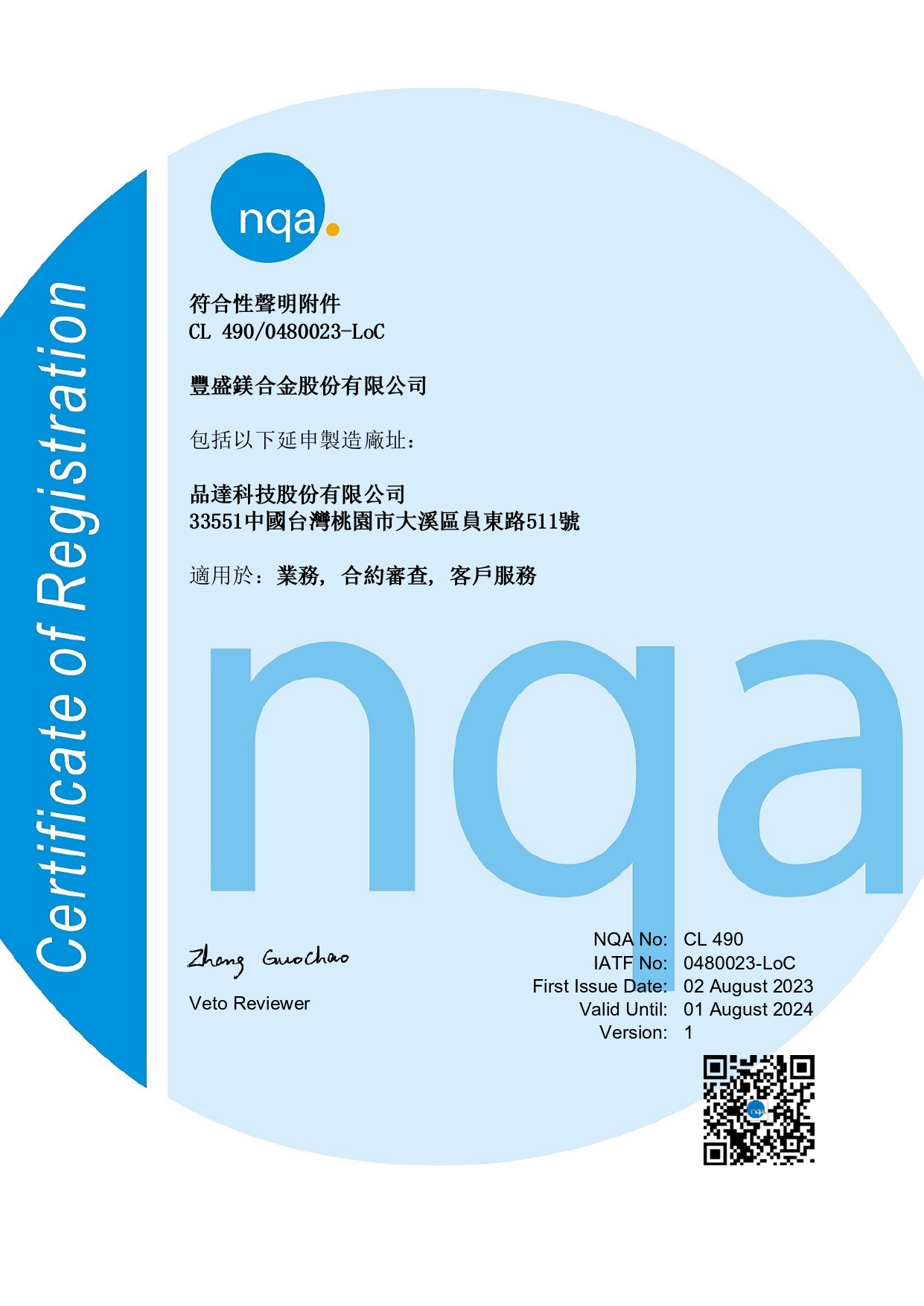

Quality

Certification

Our commitment to quality and environmental protection is reflected in our comprehensive service standards. Through stringent quality management systems such as ISO-9001 and IATF-16949, we ensure that our products meet the highest standards at every stage. This is not only evident in our manufacturing processes but also includes material certifications.

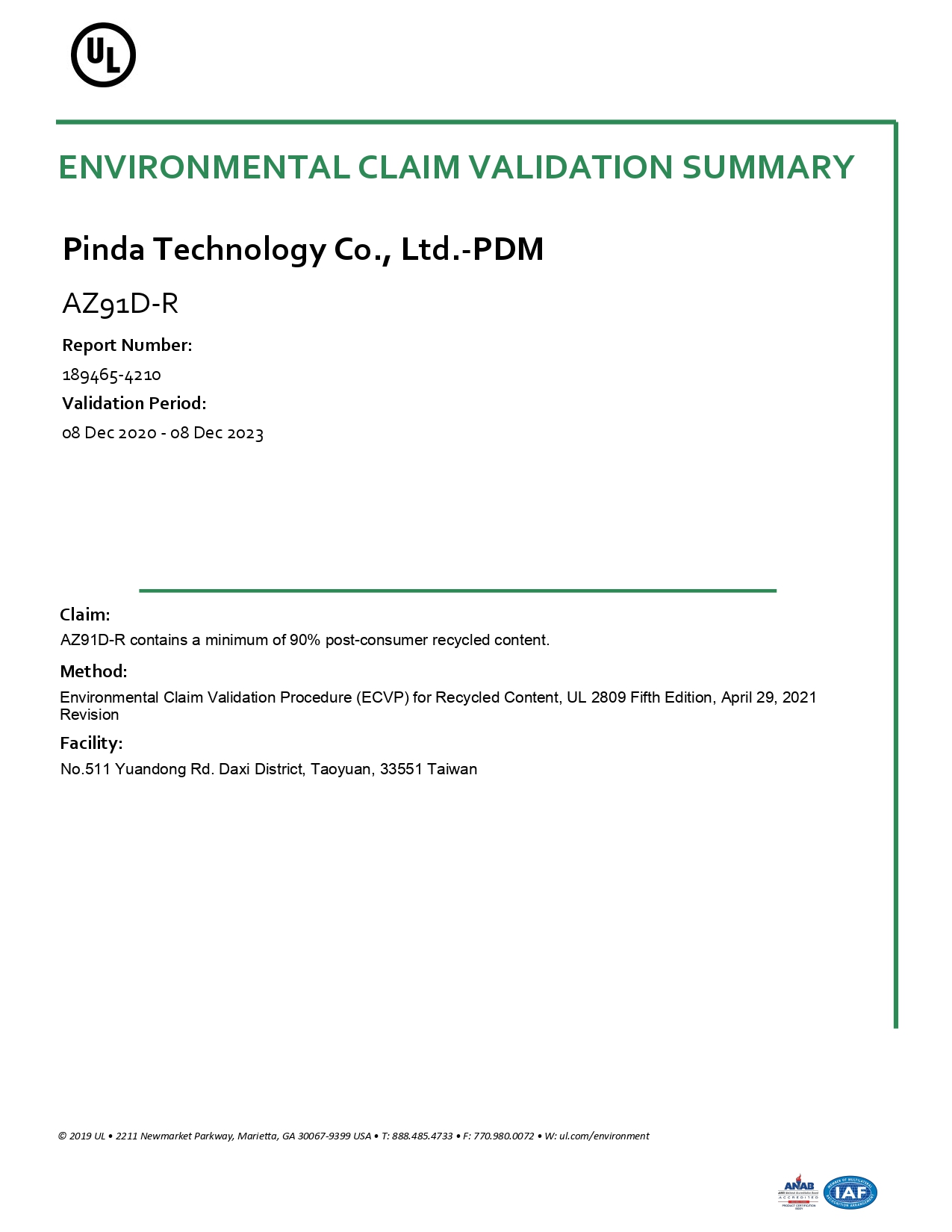

We are dedicated to environmental protection and achieve sustainability through material certifications such as PIR (Post-Industrial Recycled) and UL PCR (Post-Consumer Recycled). This means we incorporate recycled materials into our production processes, reducing the demand for natural resources while minimizing environmental impact.

_page-0002__24E08u0tVq.jpg)

_page-0001__24E08SyotR.jpg)

_page-0002__24E08u0tVq.jpg)

_page-0001__24E08SyotR.jpg)